Windmills – The precise date of Windmills’ Introduction to England is uncertain & in the past claims for an early-date have been advanced on the basis of extremely weak Documentary Evidence. The 1st certain mention is believed to be of a Post-Mill at Weedly, near South Cave in East Yorkshire, in 1185. This was on an Estate owned by the Knights Templar & some favour the idea that Windmills were introduced to England by Crusaders who had seen them in the Middle East – even if there is scant evidence for early-Windmills there. Oxfordshire Mills

Post Mills: The Mill’s supporting Post needs to be a substantial piece of Timber to carry the weight of the Mill’s Superstructure & Machinery. That which supports Pitstone Mill was cut from a Single Tree, some 17-ft long by 33-ins in dia at its Base, comparable in Girth to a Sailing Ship’s Mast. The Post is Capped with a Bearing, which permits Rotation &, via a massive Wooden Cross-beam called the ‘Crown Tree’, supports the full weight of the Mill. The Post appears to rest upon the Cross-trees beneath it, but this is not so. Were it to be, the entire weight of the Mill would bear down on their Centre, which would eventually fracture under the Pressure. Thus, the Post is suspended slightly above the Cross-trees by 4-‘Quarter Bars’, which are Morticed into it & which also maintain its Vertical position. By this means the Mill’s Weight is transferred Downwards evenly through each of the Quarter Bars & onto the 4-Brick Piers. The Cross-trees, which are held in a permanent State of Tension by the outward Thrust of the Mill’s Weight, prevent the Quarter Bars from spreading, a clever resolution of Forces.

Windmills

By the end of the 12thC, England had some 56 known Windmills, the earliest Built before 1137, compared with only 3 or 4 known in the rest of Western Europe. These early Windmills were Post Mills.

In Post Mills, the Buck, or Main Body of the Mill, contained all the Machinery: Sails, Gearing & Grindstones. Since the Mill only worked effectively if the Sails faced directly into the Wind, the Buck was supported on a Post & could be pushed around by a Tail Pole with Cartwheel to face into the Wind. In the 13thC, the Tower Mill was Developed. This had a Fixed Tower containing the Machinery, with the Sails mounted on a Cap which could be turned into the Wind. Windmills with Wooden Towers were called Smock Mills.

The design of most Windmills is what is known as a Post-Mill. This means the whole Superstructure of the Mill rests on 1–Main Post. This Post arises from Ground-Level through Brick Piers & a Brick Foundation Chamber; the Post then acts as a Pivot for the Timber Built Buck Structure above with the Sails. Consequently, the Upper Section of the Mill & Sails could be turned towards the direction of the Wind. The Mill Machinery in the upper Rotating Section was reached by External Steps.

Although uncommon, Windmills were moved occasionally, as this Account of the Procedure for Bodily removing a Post Mill explains.

“If the Main Post & Crosstrees were to be retained, they might be removed complete with the Mill Carcass; the Crosstrees would be Shored up, Brick Piers Demolished & the Trolley run underneath the Structure, which was then let down bit by bit with Jacks & Levers. Sometimes in Suffolk 2 ‘Drogues’ (or Timber-Wagons) were Lashed together side-by-side, 2–Arms of the Crosstrees being rested on 1-Wagon & 2 on the other – many Horses or Oxen were then Teamed to Haul the resulting Load.

But where the Mill was to be moved any distance, this could only be achieved by dismantling it; an example here is the Smock Mill at Lacy Green, which originally Stood at Chesham. In 1821, it was dismantled & reassembled some 9-miles to the West on its present Site at Lacy Green

Tower Mills – The susceptibility of Post Mills to being blown over led to the emergence of a different type of Mill called the ‘Tower’ Windmill. They were much sturdier, as their name suggests, having Towers that were built out of Stone and later Bricks. The Cap on top of the Windmill was still Timber & could be turned by using a Tailpole attached to the Cap that extended to Ground Level. This allowed the Sails to be moved into the Wind easily. As the early Windmills had no brakes the Sails could only be Stopped again by moving them out of the Wind. By the end of the 13thC the Masonry Tower Mill, on which only the Cap is rotated rather than the whole Body of the Mill, had been introduced. The spread of Tower Mills came with a growing economy that called for larger & more stable sources of power though they were more expensive to Build. In contrast to the Post Mill, only the Cap of the Tower Mill needs to be turned into the Wind so the Main Structure can be made much taller, allowing the Sails to be made longer, which enables them to provide useful work even in Low winds. The Cap can be turned into the Wind either by winches or gearing inside the Cap or from a Winch on the Tail Pole outside the Mill. A method of keeping the Cap and Sails into the Wind automatically is by using a Fantail, a small Windmill mounted at right-angles to the Sails, at the rear of the Windmill. These are also fitted to Tail Poles of Post Mills and are common in Great Britain.

This Tower Mill still survives. Originally Built in 1760 (a date stone stating 1806 misleads), it had Common Sails & 2-Pairs of Millstones. It was in working order in the early-1900s & then fell into disrepair. In 1925 it was almost derelict & had become partly overgrown with ivy. The Cap was repaired in the late 1970s. Sails & Fantail fitted 25th June 2014. Sails turning for National Mills Weekend – 14th May 2016.

Dave Empringham – vastly experienced in Mill Restoration. Originally worked as a Furniture Designer. Drawn into Millwrighting through volunteer Work at Lacey Green Tower Windmill in the late-70’s. Formed a Millwrighting Company with like-minded Individuals and pursued this full time. Now self-employed.

Steve Empringham – Dave’s son! Worked as a Forensic Scientist for 15-yrs before leaving the Rat Race. Now learning the Mill Restoration Trade & using recently learnt welding skills.

Karl – another vastly experienced Millwright. Fascinated by Mills from a young age, cycling the country to spot them! Trained at College whilst working with Dave & has worked on many Projects with him since.

A Date Stone exists, marked 1806, but it is thought that the Mill had been constructed in 1760. It was a Tower Mill, with common Sails, meaning an open Wooden Frame bearing the Sail Cloth. Ironwork dated 1889 suggests repairs at that time, involving Winding Gear & Curb Cogs but it is thought the Mill came to the end of its working life sometime before the WW1.

A Tower Mill is a type of Windmill which consists of a Brick or Stone Tower, on top of which sits a Roof or Cap which can be turned to bring the Sails into the Wind. The Rotary abilities gave it great convenience over the earlier Post Mills that allowed for a more efficient & stable source of Power. Windmills, in General, had been known to Civilisation for Centuries, the Tower Mill represented an improvement on the Western-style Windmills. The Tower Mill was an important source of Power for Europe for nearly 600-yrs from 1300-1900, It represented a modification or a demonstration of improving & adapting Technology that had been known by humans for ages. Although these types of Mills were effective, some would argue that they were mainly Built by more wealthy Communities at 1st because of their Complexity’

Smock Mill at Lacy Green, which originally Stood at Chesham. In 1821, it was dismantled & reassembled some 9-miles to the West on its present Site at Lacy Green

The advantage of the Tower Mill over the earlier Post mill that it is not necessary to turn the whole Mill (Body or Buck) with all its Machinery into the Wind; this allows more space for the Machinery as well as for Storage. However, select Tower Mills were Constructed on a Wooden Frame so as to rotate the entire foundation of the Mill along with the Cap. These Towers were often constructed out of Wood rather than Masonry as well. A movable head which could Pivot to react to the changing Wind patterns was the most important aspect of the Tower Mill. This ability gave the advantage of a larger & more Stable Frame that could deal with harsh weather. Also, only moving a Cap was much easier than moving the entire Structure.

In the earliest Tower Mills the Cap was turned into the Wind with a long Tail-pole which stretched down to the Ground at the back of the Mill. Later an endless chain was used which drove the Cap through Gearing. In 1745 an English Engineering Blacksmith, Edmund Lee Invented the Windmill Fantail – a Ring of 5 to 8–Vanes mounted behind the Main Sails at right-angles to them. These were connected by Gears to Wheels running on a Track around the Cap of the Mill. As the Wind changed Direction, it struck the sides of the Fantail Vanes, gradually realigning them and thereby turning the Main Sails again Squarely into the Wind.

A Fantail is a small Windmill mounted at Right-angles to the Sails, at the rear of the Windmill, & which turns the Cap automatically to bring it into the Wind. The Fantail was Patented in 1745 by Edmund Lee, a Blacksmith working at Brockmill Forge near Wigan, England, & perfected on Mills around Leeds & Hull towards the end of the 18thC. Fantails are found on all types of Traditional Windmills. They are more common in England, Denmark & Germany than in other parts of Europe & are little-known on Windmills elsewhere except where English Millwrighting Traditions were in evidence. The rotating Fantail turns the Cap of Windmill via a System of Gearing to a Roothed Rack around the top of the Mill Tower, or to Wheels running on the ground in the case of a Post Mill (Chinnor). It does so until the Fantail Sails are oriented Parallel to the Wind, as in this case, the Wind can no longer move them. When the Fantail is oriented Parallel to the Wind, the Main Sails are in the optimal Perpendicular Orientation and therefore produce Maximum Power regardless of any slight or continuous Windshift.

Stock – the Arm that protrudes from the top of Windmill holding the Frame of the Sail in place, this is the Main Support of the Sail and is usually made of Wood.

Sail – the turning Frame that catches the Wind, attached & held by the Stock. The traditional style found on most Tower Mills is a 4-Sail Frame, however, in the Mediterranean model, there is usually an 8-Sail Frame. An example of this Buzza Tower Mill in St Mary’s Mill on the Isle of Scilly constructed in 1821.

Windshaft – A particularly important part of the Sail Frame, the Windshaft is the cylindrical piece that translates the movement of the Sail into the Machinery within the Windmill.

Cap – The top of the Tower that holds the Sail & Stock, this piece is able to rotate on top of the Tower.

Tower – Supports the Cap, the Main Structure of the Tower Mill.

Floor – Base level of the Tower inside, usually where Grain or other Products are stored.

Gallery – Deck surrounding the Floor outside the Tower to provide access around the Tower Mill if it is raised, not present in all Tower Mills. The Gallery allowed access to the Sails for making Repairs because they could not be easily reached from the ground in Larger Mills.

Frame – Sail design that forms the Outline of the Sail, usually a meshed wood design that then is covered in Cloth. The Mediterranean design is different in that there are several Sails on the Sail-frame and each supports a draped cloth and there is no Wooden Frame behind it.

Fantail – Orientation Device that is attached to the Cap, allowing it to rotate to keep the Sails in the direction of the Wind

Hemlath – Thick Wooden Sailbar on the side of the Frame that keeps the narrower Sailbars inside the Sail.

Sailbar – Elongated piece of Wood that forms a Sail.

Sail cloth – Cloth attached to a Sail that collects Wind Energy; a large Sailcloth is used for weak Winds and a small Sailcloth for strong Winds.

Water Power – The earliest Watermills date to the Romano-British Period. There then appears to have been a hiatus; the earliest known Anglo-Saxon Mills have been dated to about AD 700. The Domesday Book (1086) Documents some 5,624 Watermills, some known to have had their Origins in the Centuries before the Norman Conquest, others already Derelict. Watermills were used throughout the Medieval Period & into the early-20thC; many underwent several phases of reconstruction & were in use for Centuries – a few survive in use today – though others had shorter lives. They frequently changed functions & some had 4 or more distinct Roles; while each of these required an internal refit, the Water Management Works probably needed little if any modification. In the industrial period many Waterwheels were replaced by Steam-engines, or later by Internal Combustion Engines & Electric Motors, often utilising the same Buildings. A chronological development from Horizontal to Vertical Wheels has been suggested but this is unlikely to be the case. The known Romano British Wheels were all Vertical & although most early Anglo-Saxon examples were horizontal, one of the earliest known examples, at Old Windsor (Berks), was Vertical. It is not known how many of the Mills mentioned in the Domesday Book were horizontal but by the 13thC they had apparently disappeared from England (although ‘Norse’ Mills continued in use in the Shetlands into the 20thC).

To harness the Latent Power of flowing Water in order to generate a useful source of Power was an equally challenging task. Building an efficient Watermill required many similar skills to those of Building a Windmill, as well as a number of different ones. The Millwright was an expert Architect, Carpenter, and also an Engineer; for not only did he construct the Mill itself but all the Machinery within, – every part of which played an essential role in the intricate Milling Process. Although Minor, and in some cases Major, Technical or Structural repairs were occasionally undertaken by the Miller himself, these were usually the responsibility of the Millwright who was required to return the Mill to working order with all due speed, for on this the Miller’s livelihood was dependent.

Watermills – can be divided into 2-basic types, one powered by a Vertical-waterwheel via a Gearing mechanism & the other equipped by a Horizontal-waterwheel without such a Mechanism. The former type can be further divided, depending on where the water hits the Wheel-paddles, into Undershot, Breastshot, Pitchback or Overshot Waterwheel Mills. The earliest Mill consisted of a Horizontal-waterwheel set in a Watercourse so that the forces of the stream pushed the Paddles around, the Axle passing up through the Floor of the Mill to drive Millstones which crushed the Grain. It was probably the Romans who devised the necessary gearing to enable Vertical-water wheels to be used. By the time of the Domesday Book in England, every Settlement with access to running water had its own Watermill.

Building a Watermill took weeks or even months of Labour. No Machinery or standardised parts were available, only human strength and ingenuity. Except for a few (metal) parts the Blacksmith might Forge, everything had to be made from Wood and Stone. The Millwright was called in for the Job. The Millwright found a good Site. Foundation walls were erected. Logs were cut & fashioned into Beams, Boards & Shingles. Pillars were constructed to support the Water-wheel Shaft. The Millwright located a White Oak Tree for the Water Wheel Shaft. Only the Millwright had the knowledge of what Woods was best to use for different Parts. The Water-wheel, Gears & Bearings were made. Sometimes Stone or Wood was used for Bearings. Stone Bearings were lubricated with either Water or Tallow. Wooden Bearings were Lubricated with Tallow. A Dam, Mill Race & or a Sluice Box was constructed. Finally, the Mill was ready to be set into Operation. The 1st Grain was Ground & the Mill was Tested. No one dared ask the Millwright about his work, he went about it in silence, few people were lucky to watch him Work, he safeguarded his Trade Knowledge. No one dared ask him questions, what he was doing or why, because it is a well-known fact that a Millwrights Spit can kill a Toad.

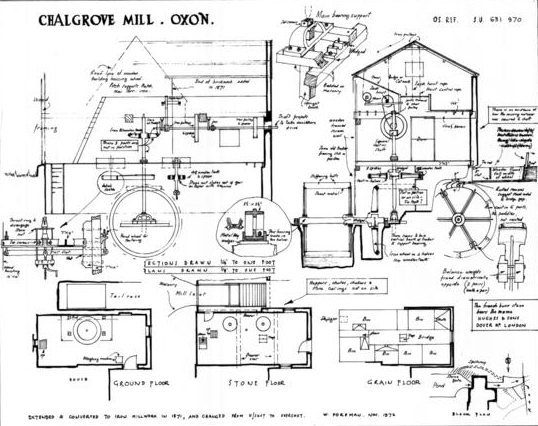

Chalgrove Watermill, Mill Lane – Watermill & Millhouse, now House. 17thC Millhouse with mid-18thC right bay. Originally Timber-framed, some Timber-framing with Brick infill to Rear; roughcast Front;. mid-18thC English bond Brick to Rear right. Gabled Roof, 20thC Tiles to Rear, old Tiles to Front; late 19thC left end Stack. 2 extended to 3-unit Plan. 2-Storeys; 2-window Range. Early 20thC Door & Casements.

Interior: chamfered & stopped Beams: Timber-framed central portion & right side wall on 1st-Floor. Late 18thC panelled Door & ribbed Doors. Roof not inspected. Mill to Right dated 1871/AF, of Brick with Gabled Welsh Slate Roof, is attached to Weatherboarded Building on right housing an Iron Overshot Wheel. Mill Race at rear with Leat to right. (Wilfred Foreman, Oxfordshire Mills, 1976, p.135). The Mill Race was also used as a Sheep Dip

As you look at the various Types of Water-wheel, you will also see that they tend to have characteristic Bucket shapes. The Overshot wheel normally having straight buckets set tangentially to the wheel, the Breast-shot Wheel having heavily curved buckets & the Undershot Wheel simply having straight paddles sticking out from the Rim. There are 4-main types of water wheel – The ‘Overshot’ on which Water enters the Buckets at the top on the down-running side; The ‘Undershot’ where Water flows underneath the Wheel which is more like a large Paddle; The ‘Breastshot’ where water enters the Buckets at about the Middle of the Wheel & The ‘Pitchback’ on which the Water enters the Buckets at the rear of the wheel beneath the Pentrough. Overshot & Pitchback Wheels are more efficient than the other Type because they are driven both by the weight of Water [1-cubic foot (28-litres) weighs 62-lbs (28-kg)] & by the Force or Pressure of Water directed into the Buckets by the ‘Pentrough’. Both types of Wheel require a good “Head of Water” that is the difference between the height of Water in the Millpond & the Tailrace. The Power & to some extent the Speed of the Wheel are determined by the amount of Water flowing into it, that is, by flow (mass per unit time) & Fall. The Flow is controlled by the ‘Penstock’ (a Sluice Gate) located in the Pentrough, which is raised & lowered by a Rack & Pinion turned by a Lever on the Stone floor behind the left-hand pair of Stones. The higher the Penstock, the greater the Flow (mass) of Water. The Fall is given by the Head of Water mentioned above. It has been calculated that such Wheels could generate about 10-hp.

Millers everywhere continued to use the Ancient methods of Wind & Watermills. Besides the House, the Stool, the Water-wheel & other driving parts, there were, we see, only 2-Millstones to grind the corn, a spout to catch the Meal, and a Trough to receive it, out of which it was taken by the Sifters. The Sukkyne, or sucken, was the area from which the Dusty Miller drew his Business. He was entitled to have the Milling of all the Corn grown on his Sucken, except what was required for Sowing the next Crop. The Duty, consisting of a proportion of the grain, exacted by the Proprietor or Tenant of a Mill on all Corn ground. Insucken multure was that exigible from Farmers within the Sucken of the Mill and was heavier than Outsucken multure, levied on those Outside the Sucken who came voluntarily to the Mill. Dry Multures are Duties, in Grain or Money, paid by Suckeners whether Grain is ground or not. The chief Dues for such Grindings were called Multures and the lesser Dues Sequels.

Watlington Watermills: Marlbrook, the Stream that runs through Watlington, drove 3-Mills within a mile of each other. One was in Cuxham & 2 in Watlington. Both the Watlington Mills were on Robert d’Oilly’s Manor in 1086 & were worth 10s & 8d respectively. In about 1170 Halinad de Bidun & his wife Agnes, who held this D’Oilly Manor, gave 1-Mill called Sobeford to Oseney Abbey. Oseney remained in possession of this Mill until the Dissolution of the Abbey. It was variously called ‘Sibford‘ & ‘Shefford‘ & can be identified with the later Upper Mill or ‘First‘ Mill. In the early-16thC, the Farm of this Mill brought in 13s-4d, but was said to have previously been worth 26s-8d a year; the Rent was still 13s-4d when Oseney Abbey was dissolved. In 1547 the Mill was given to the Bishop of Oxford with the rest of the Rectory Estate. It continued to be Leased: in 1590 a John Stacy obtained a Water-mill from Robert Wright and his wife, and in 1634 John Stacy’s son John received ‘the freedom‘ of Shefford Mill. This was one of 2-Water-Mills working in 1718; it was owned by the Hornes & then by the Hultons in the 19thC & was known as First Mill or Mill Farm. Mill Farm was Sold in 1897 when the Mill was described as ‘in excellent order and capable of doing a considerable Business,’ but there is no later record of its use as a Mill.

The other Domesday Mill, known later as the Middle Mill, was likewise given to a Religious House, when c.1215 William Paynell & his wife Sarah, who then held the D’Oilly Manor, gave their Mill, called Wochemulne, with a Messuage, 2-acres, and Timber Rights for the repair of the Mill to the Nuns of Godstow. The Paynells’ successor, Peter Fitz Herbert, confirmed this Grant, but Godstow must have lost the Mill, probably when the King took the Manor back into his own hands in 1223, for they Held no Property in Watlington in the later-13thC. In 1272 the Mill, worth 26s-8d a year was again attached to the Principal Manor & in 1285 Edmund, Earl of Cornwall’s Rights in the Mill were acknowledged by a John le Mouner & Robert d’Oilly. In the 15thC, this Mill was Leased for a term of years: in 1460 the new Tenant took it up for £2 a year & was to repair & mend all parts, the Millstones, Cogs, Floodgates & Woodwork as well as the Tiles & Roof & to return it in good condition & worth £5. In William Spythurst renewed his lease for 21-yrs paying 1s-4d new increment & a Rent of £3-6s-8d a year; in 1608 a Richard Smith paid an annual rent of £3-8s for the Mill & Hayhouse, which he held on a 21-yr Lease. This may have been the 18thC Water driven, Corn, or Grist Mill, mentioned in 1738, but it is difficult to distinguish between the 2-Watermills in Deeds of this Period since they were both in use. In the 19thC the Hultons owned this Mill as well as the Rectory Mill & ‘Watlington Middle Mill‘ was also put up for Sale in 1897. The last-named appears to be the same as the Steam & Water-Mill occupied by John Tappin in 1893 & was again offered for Sale in 1911 when Moses King was Miller, but there is no later record of it.

The Animal Food was Sold mainly to local Smallholders & Cottagers to feed their pigs & chickens, but as these enterprises diminished the Mills gradually fell into disuse.

In the Middle-Ages, a 3rd Mill belonged to the Stonors, who held the Préaux Abbey Estate. It was a Horse-Mill & probably stood on the Hill. It was described as ‘quite ruined‘ in 1361 & in 1384 as ‘out of repair‘ & eventually it was taken into the Lord’s Hands. In 1481 William Stonor Leased it to Christopher Holand of Thame for 80-yrs at 26s-8d a year. There was still a Horse-Mill on this Estate in the 16thC. By 1615 John Simeon of Brightwell Baldwin Held it: it was called a Horse-Malt-Mill.

A Horse Mill is a Mill, sometimes used in conjunction with a Watermill or Windmill, that uses a Horse as the Power source. Any Milling process can be powered in this way, but the most frequent use of Animal Power in Horse Mills was for grinding Grain & Pumping Water. A 4-Horse Mill requires a large working space.

Progression; A few progressive men strove to free themselves from the restraints of waiting on the Wind & Water to drive the Mill Machinery. In the middle of the 19thC, a Swiss Engineer Invented a new Type of Mill (1874); abandoning the use of the Stone Mill-wheels, he designed Rollers made of Steel which operated one above the other. It was called the Reduction Roller-milling System, & these Machines soon became accepted all over Europe & in Britain. They were driven by Steam-Engines, which had by now much improved, and the new method proved a great success. So popular did they become, that within about 30-yrs from their introduction into Britain in 1880, more than 75% of the Windmills & Watermills which had served so faithfully (if sometimes erratically) for 100s of years, were demolished, or left to Rot. Meanwhile, the Development of the North American Prairies, ideally suited to grow Wheat, provided ample Grain for the fast-growing Population of Great Britain at the time of the Industrial Revolution (which in turn reduced the Farm Acreage here). This, together with the Invention of the Roller-milling System, meant that for the 1st-time in History, whiter flour (& therefore the Bread) could be produced at a Price which brought it within the reach of everyone – not just the Rich.