Small-scale Brewing was common in Medieval Berrick, 6-Tenants being Fined in 1462/3 for Breaching the Assize of Ale. A Medieval Seal inscribed with the name of John le Tanner of Berrick was Found in the late-19thC, but generally Traditional Rural Crafts were mentioned only sporadically, suggesting reliance on neighbouring Places. A Weaver, Cordwainer, Carpenter & Blacksmith were briefly mentioned in the 1720s-30s, and the Farmer Richard Wise (d.1778) ran a Shop selling Groceries & Chandlery. Even so in 1811 only 3-Families were supported by Trades or Crafts, compared with 30 by Agriculture. Small-scale Malting may have begun c.1678 when a Henley Maltster took up a Berrick Salome Copyhold and by 1762 there was a Malthouse at Lincoln Colleges Malt House Farm. In the early 19thC it was run by the prosperous Maltster Thomas Weller (d. 1817), but apparently ceased operating soon after.

Malting is the process of converting Barley or other Cereal Grains into Malt for use in Brewing, Distilling, or in Foods and takes place in a Maltings, sometimes called a Malthouse, or a Malting Floor. The Cereal is spread out on the Malting Floor in a Layer of 8 to 12-cm (3 to 4.5-ins) depth.

Drying: the Malting process starts with drying the Grains to a moisture content below 14% and then storing for around 6-weeks to overcome Seed Dormancy.

Steeping: when ready, the Grain is Immersed or Steeped in water 2 or 3 times for 2 or 3 days to allow the Grain to absorb moisture & to start to Sprout.

Germination: when the Grain has a moisture content of around 46%, it is transferred to the Malting or Germination Floor, where it is constantly turned over for about 4 to 6-days while it is Air-dried.

Pre-toasting: the Grain at this point is called “Green Malt“. The Green Malt is then dried & pre-toasted in an Oven (or Kiln) to the desired colour & specification. Malts range in colour from very Pale through Crystal & Amber to Chocolate or Black Malts.

Smoking: the Sprouted Grain is then further Dried & Smoked by spreading it on a Perforated Wooden Floor. Smoke coming from an Oasting Fireplace (via Smoke Channels) is then used to heat the Wooden Floor & the Sprouted Grains. The temperature is usually around 55°C (131°F).

A “Maltings” is typically a long, Single-Storey Building with a Floor that Slopes slightly from one end of the Building to the other.

Floor Maltings began to be phased out in the 1940s in favour of “Pneumatic Plants” where large Industrial Fans are used to Blow Air through the Germinating Grain Beds and to pass Hot Air through the Malt being Kilned. Like Floor Maltings, these Pneumatic Plants use Batch Processes, but of considerably greater size, typically 100-Ton Batches compared with 20-Ton Batches for Floor Maltings.

The Malt House, Berrick Salome: 17thC, Extended 18thC. Clunch rubble with Timber Lintels & some Brick Quoins & Timber Framing; Thatch & old plain-Tile Roofs with Brick Stacks. 3-Unit Plan, extended 2-Storeys plus Attics. 4-window Front has, to extreme Left, later projecting Wing, with Brick Quoins; Central Bays have Entrance flanked by 20thC windows, but retain an eroded Rubble String linked to Label Drops. Tiled Bay, to extreme Right, is also a later Extension and has a half-Hipped Roof. Roof over Central Bays has 2-Roof Dormers and a highly-ornamented Brick Stack to Right. Left end Wall of Main Range has a partly-Weatherboarded Timber-framed Gable with Rubble Infill. Rear Wall has similar String & Labels.

Interior: some Chamfered & Stopped Beams.

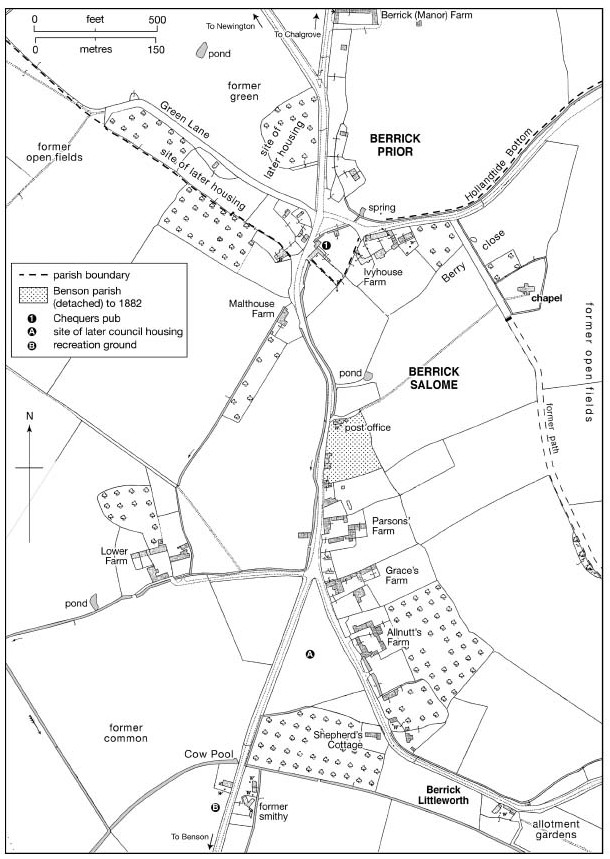

Craftsmen in 1841 (some probably based in the Berrick part of Roke) included a Thatcher, Hurdlemaker, Wheelwright, Shoemaker, Tinman & Blacksmith. The Gale Family’s Carpentry & Wheelwrights’ Business at Cow Pool in Berrick continued until WW1, and a nearby Smithy into the 1870s, the Village relying thereafter on 2-Benson Blacksmiths who visited with a portable Forge. Two small Shops in 1851 included James Jacobs‘ Grocery, which sold Beer and continued in the 1880s, while other Beer Shops or Off-licences included the Plough & Harrow (now Plough Cottage) on Berrick Street.

More unusual late-19thC Tradesmen included a ‘Canine Merchant’, a Coal & Corn Dealer, Bricklayers, a House Decorator, a Plumber & a Chimney Sweep, while a few Women worked as Dressmakers, Laundresses, or Charwomen. A Veterinary Surgeon was mentioned in 1871, and an Insurance Agent in 1901. By 1939 Traditional Crafts were apparently confined to Roke & Rokemarsh, and though Berrick Inhabitants included a Decorator, Insurance Agent, and the Postmistress-cum-Shopkeeper, Employment thereafter became increasingly Focused Outside the Village.